ENQUIRIES 01482 485 170

Your Home On Firm Foundations

Our Versatile & Robust Chassis

Product Range

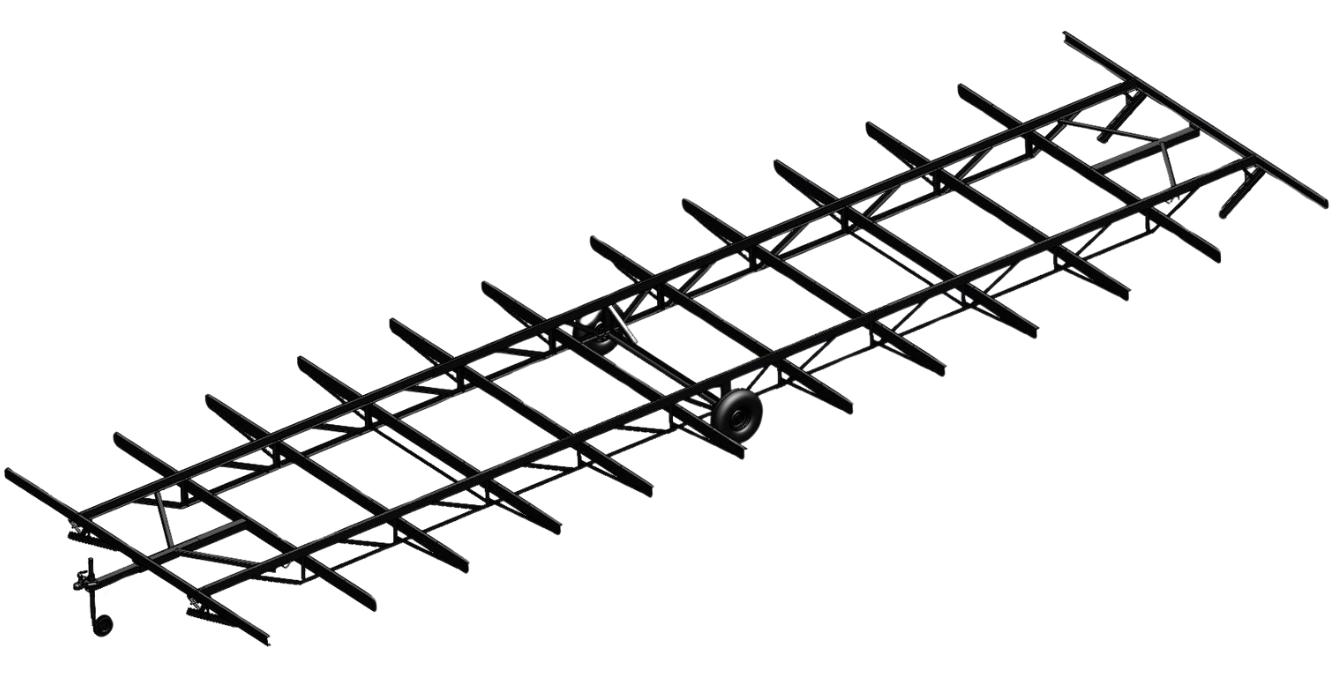

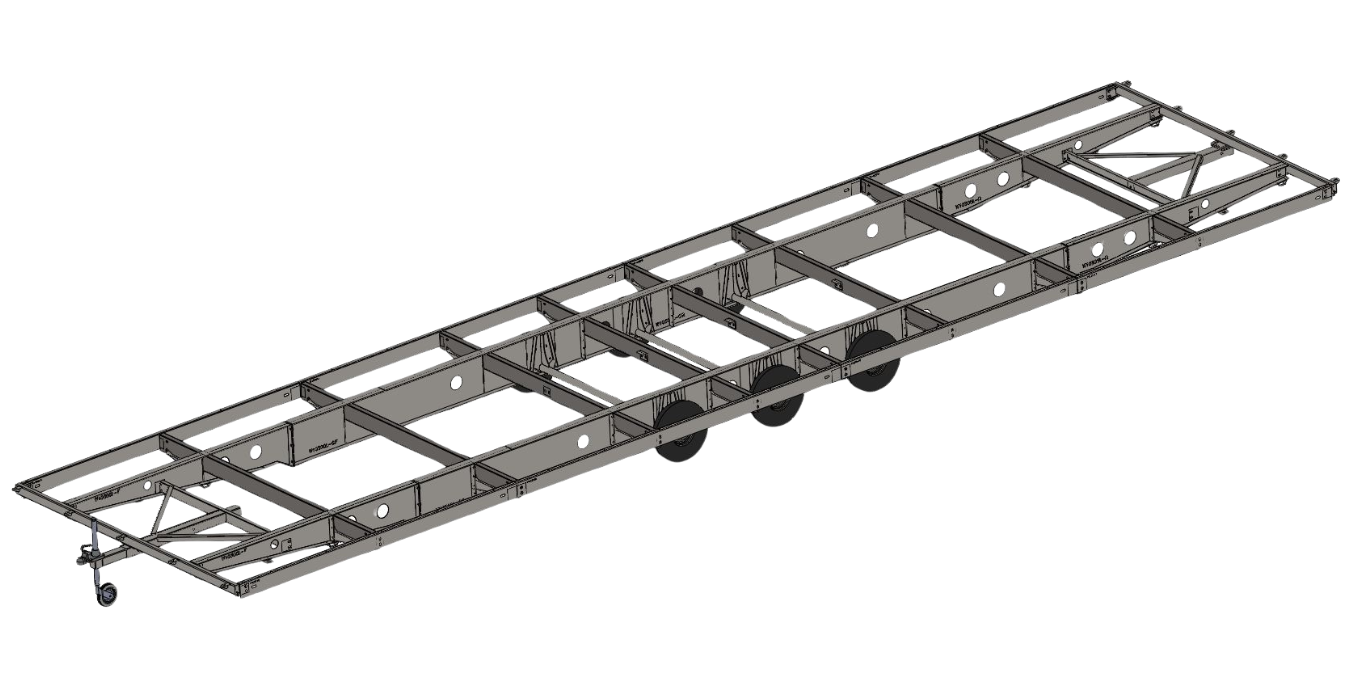

Conventional Chassis

Designed specifically for caravan holiday homes, our conventional chassis embodies a traditional design that has been a staple in the industry for generations. It features welded sections and is coated with a UK-manufactured paint designed specifically for this sector complying with residential specification BS3632.

This chassis offers an economical solution for temporary structures with lighter loads in less corrosive environments. This chassis can be up to a maximum length of 42ft and can accommodate up to two axles. Furthermore, a pre-galvanised option is available for this welded chassis.

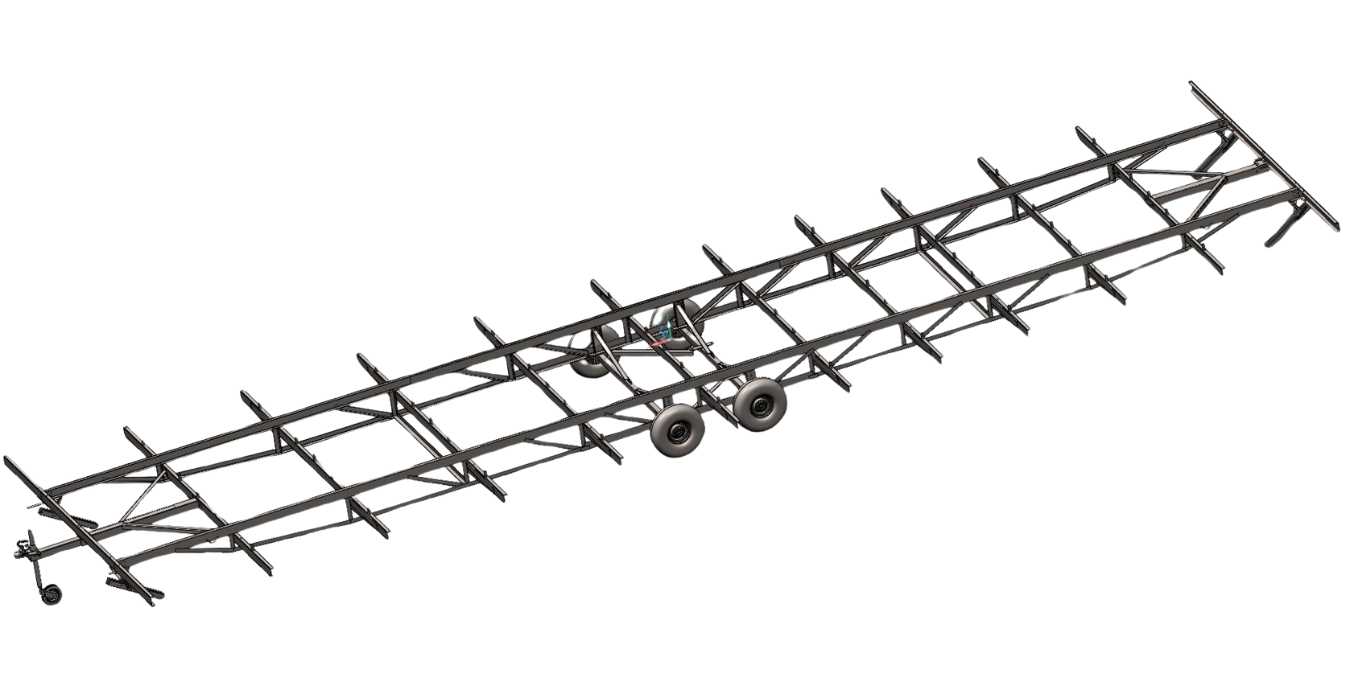

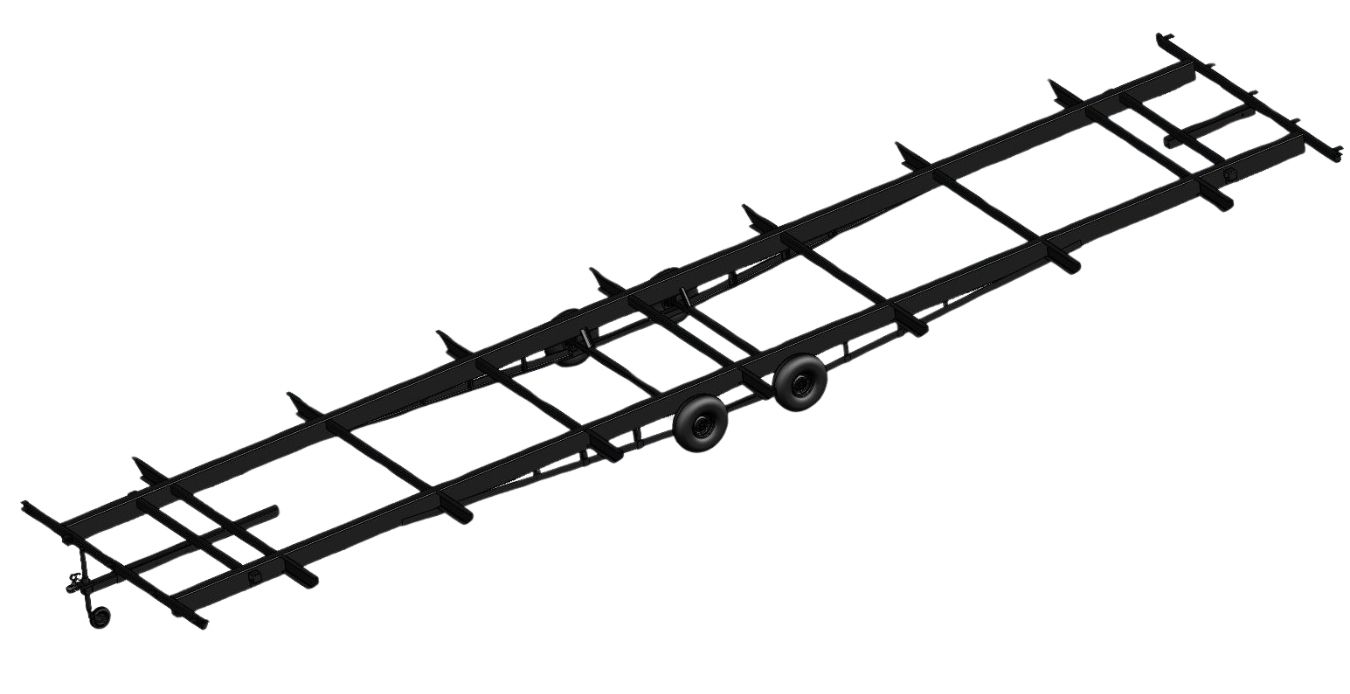

Split Sectional Chassis

Our Split Sectional chassis is a unique design that meets residential specifications BS3632, and is tailored for medium to higher end Caravan Holiday Homes and Leisure Lodges.

This chassis is constructed in segments, and hot dipped galvanised to offer enhanced corrosion resistance. The galvanised segments are assembled using rivets and bolts with galvanised components, resulting in a sturdy chassis ideal for medium to high-load structures. This chassis can be up to a maximum length of 42ft and can accommodate up to two axles.

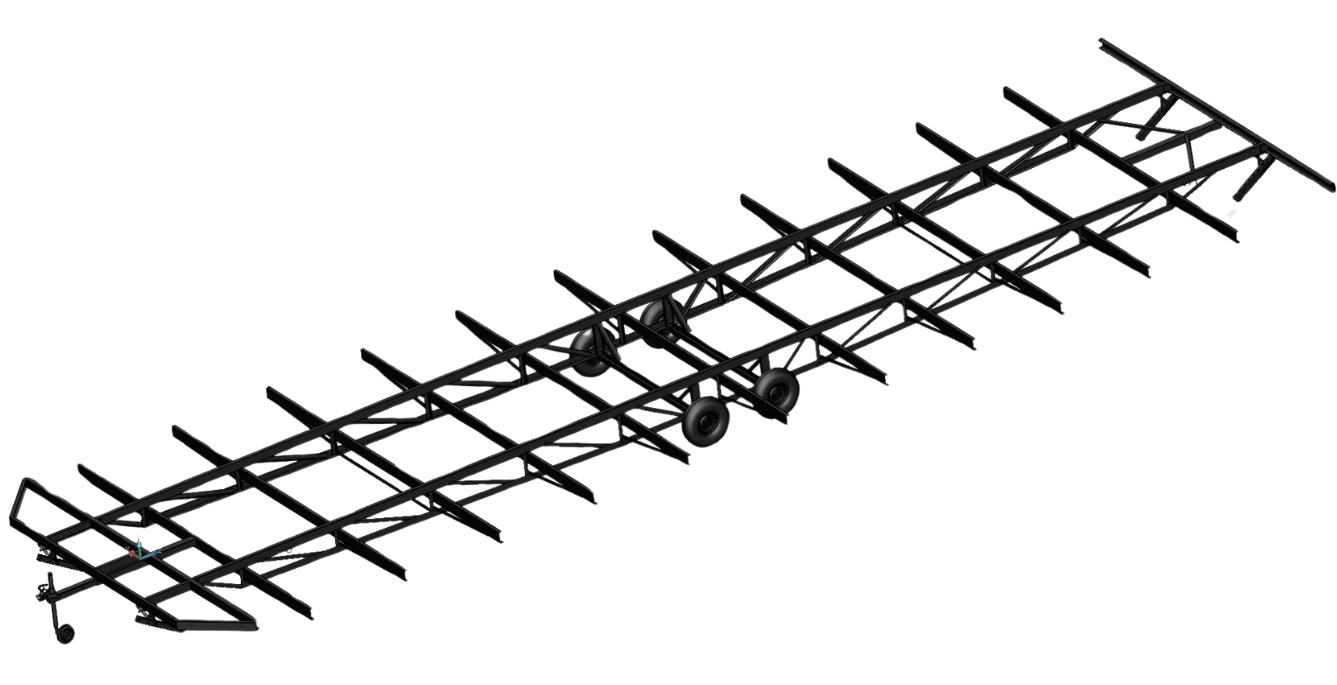

Residential Chassis

Our Residential chassis, tailored specifically for caravan holiday homes, is a variation of our conventional chassis design, providing a cost-effective option for heavier structures exceeding 42 feet in length.

This classic design, which has been used in the industry for decades, includes welded sections and is finished with a specialised paint produced in the UK. It is particularly suitable for temporary and multi-unit setups complying with residential specification BS3632.

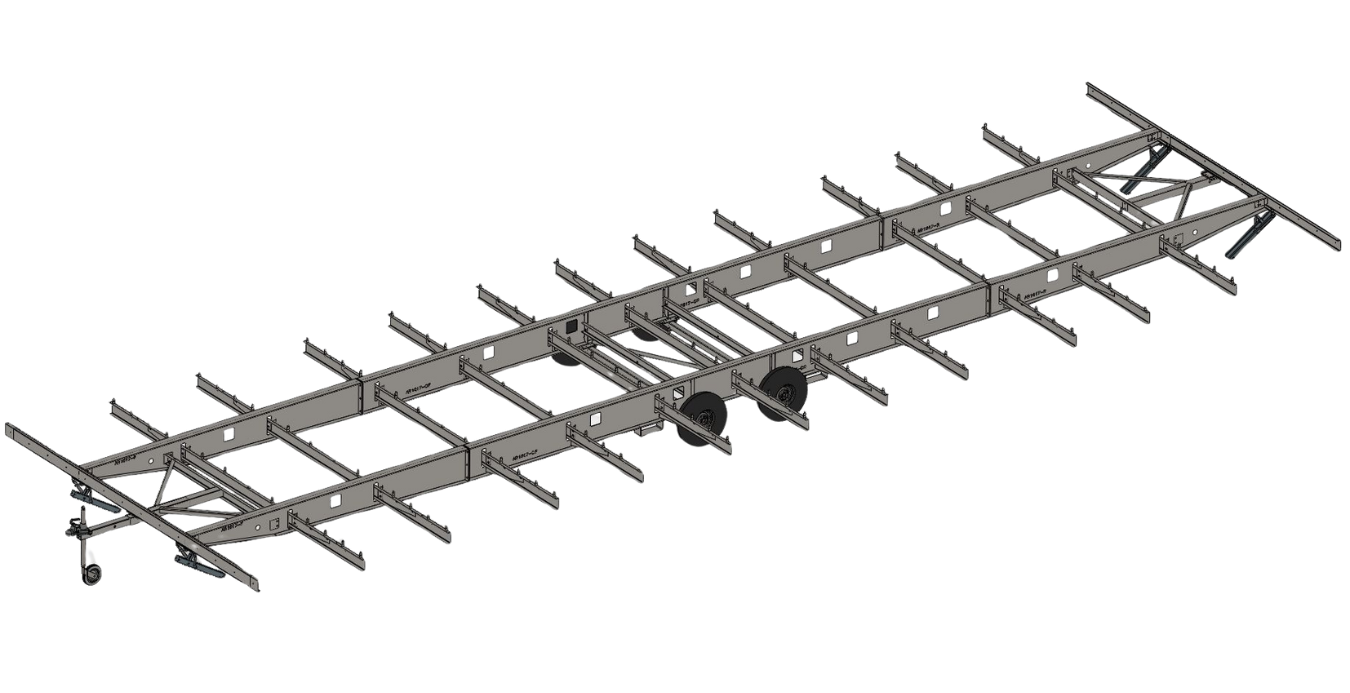

I-Beam Chassis

Developed to meet the need of a solid, robust foundation for luxury leisure lodges and park homes, our I-Beam chassis is the strongest option available on the market, boasting impressive load-bearing capacity and complying with residential specification BS3632.

The chassis is fully galvanized, ensuring exceptional corrosion resistance. Thanks to the expertise of our design engineers and research and development team, we have optimized the design for maximum durability and strength.

Park Home I-Beam

Crafted and engineered to accommodate the evolving needs of home manufacturers and the National Caravan Council for compliance with BS3632, our Park Home I-beam chassis is sectional construction and offers enhanced stiffness and strength. Its structure incorporates the highly efficient 'I-Beam design' and is available in both fully galvanized and painted finishes.

Park Home StrongBox™

Crafted specifically for Park Homes, our StrongBox™ chassis is a market -leading product, utilising box section cross members instead of the conventional c-section design. These box sections play a crucial role in maintaining the structural integrity, providing a more comfortable and stable living environment for the homeowner. Additionally, this design ensures that any redecorating or refurbishing efforts are less likely to impact the home's balance on its supporting framework.

Holiday Pod Frame - Welded

Designed with holiday pods in mind, our pod frames features welded sections with detachable axles, coated with a UK-manufactured paint tailored for this industry. It serves as an excellent option for smaller pods that want to be lower to the ground.

This frame not only offers a modern look but also enhances space efficiency, making it ideal for optimizing the interior of compact holiday pods.

Modular Pod Frame

Tailored for the residential market, our modular frames are versatile, accommodating everything from pods to home offices and living spaces.

Each frame is constructed according to our customers' specifications and dimensions before undergoing a complete galvanization process and being securely bolted together.

UK's Leading Chassis Manufacturers

Gateway Chassis | UK’s Leading Dedicated Chassis Manufacturers

We specialise in designing and manufacturing chassis to provide a robust foundation for Caravan Holiday Homes, Leisure Lodges, Residential Park Homes, and more.

Our chassis product range is versatile, catering to a vast array of applications in the caravan and leisure industries.

With a friendly, professional, and knowledgeable team, we are dedicated to selecting the best-suited product for your technical and manufacturing needs, as well as for the local environment where the structure is to be sited

Download Our Brochure

Explore our products and services in more detail. Our brochure provides a comprehensive overview of what we offer, from innovative solutions to high-quality modular buildings. Discover how we can meet your business needs with precision, durability, and flexibility.

Finite Element Analysis (FEA)

We utilise Finite Element Analysis (FEA) to optimise chassis design for maximum performance and safety. By simulating real-world conditions, FEA helps identify weaknesses early, ensuring robust, durable products.

3D CAD

Modelling

We use 3D CAD modelling to create precise designs, visualising and refining them before production. This ensures accuracy, reduces errors, and delivers faster, cost-effective solutions with improved product quality for our customers.

Sustainability & Efficiency

We focus on sustainable processes by optimising design and production methods to reduce waste, energy consumption, and environmental impact. This commitment to eco-friendly practices ensures efficient, long-lasting solutions.

Have a query regarding our chassis range? Email sales@gateway-chassis.co.uk

Our Trusted Partners

We are proud to collaborate with these trusted companies, building strong relationships to deliver the highest quality solutions

Building on a Strong Foundation

Gateway’s Approach to Chassis for Holiday Homes

The chassis may be hidden once the home is sited, but it’s essential in providing a safe, comfortable, and sustainable foundation. At Gateway, we recognise the importance of every step in the chassis journey, ensuring it meets the highest standards before reaching its final destination

1 | Bespoke Design

Every chassis is designed to suit the home that is built on it. Care and consideration are given to the load distribution of the building, positioning utilities and siting of heavy components such as kitchen and bathrooms. Using Finite Element Analysis (FEA) & 3D CAD modelling, the chassis are assessed against the anticipated home weight to ensure it meets the structural requirements of the building it will be supporting.

2 | Chassis Manufacture

The chassis are built and manufactured by highly trained welders and the non-hot dipped galvanised units are finished in our paint shop, giving them the necessary protection against the elements. Each chassis is manufactured to National Caravan Council Code of Practices and individually quality checked. We adopt lean manufacturing techniques and invest in continuous improvement to ensure our products are efficiently manufactured to the highest standards.

3 | Build & Assembly

Consideration is given during the design stage to assist the Home manufacturer with the assembly of the home in the factory. Things such as siting of utilities, ease of assembly and manoeuvrability are considered during the design stage to make things run as smooth as possible. We work very closely with home manufacturers to ensure we produce chassis that meet their production needs, we pay close attention to accuracy and squareness to ensure the highest level of efficiency during all stages of the build process, with attention to the important first stage when the floor is positioned on the chassis.

Bespoke Design

Our Process

Using 3D CAD software & FEA testing

Our design process is also just as considered. From talking to the marketplace, it’s clear that not all manufacturers use 3D modelling. To help us improve the design phase, we employ highly experienced, qualified engineers and structural analysts – all trained in 3D CAD software and FEA

- One of the rigorous ways we test and verify our chassis systems is through FEA (Finite Element Analysis) testing. This virtual method predicts how the chassis will react to real-world loading, vibration and other physical effects. Prototype systems are used to fully test products, including bespoke models built to customer specifications. Ultimately, this testing process validates whether the chassis has the strength and resilience required to stand up to rigorous use.

- This culminates in our continuous improvement process – ‘Value Added, Value Engineered’. Our ambition is to minimise the cost impact to our customers through smarter, more efficient design and manufacturing, while not compromising the strength of our chassis.

- Our high specification I-Beam Chassis is a perfect example of how the VA/VE process is used in conjunction with our stringent quality control processes. Developed to meet the demands for chassis for high-end leisure lodges and park homes, the I-Beam is structurally the strongest (in terms of load bearing capacity) available in the market. The fully galvanised chassis offers high corrosion resistance while the expertise of our design engineers and research and development team has allowed us to optimise the design for the ultimate longevity and strength.

- Building on more than ten years of market experience, the VA/VE multi-functional team has successfully completed, designed and FEA tested a new and improved I-Beam product.

Get in Touch

We Are Gateway

Have a question or need assistance? Whether you're looking for expert fabrication, modular solutions, or a trusted industry partner, our team is ready to help.

Contact us today!

Gateway Chassis

Gateway Fabrications

Gateway Modular

©Copyright 2025. All rights reserved.

We need your consent to load the translations

We use a third-party service to translate the website content that may collect data about your activity. Please review the details in the privacy policy and accept the service to view the translations.